Brown Fused Alumina (F)

Brown Fused Alumina(F)

Description

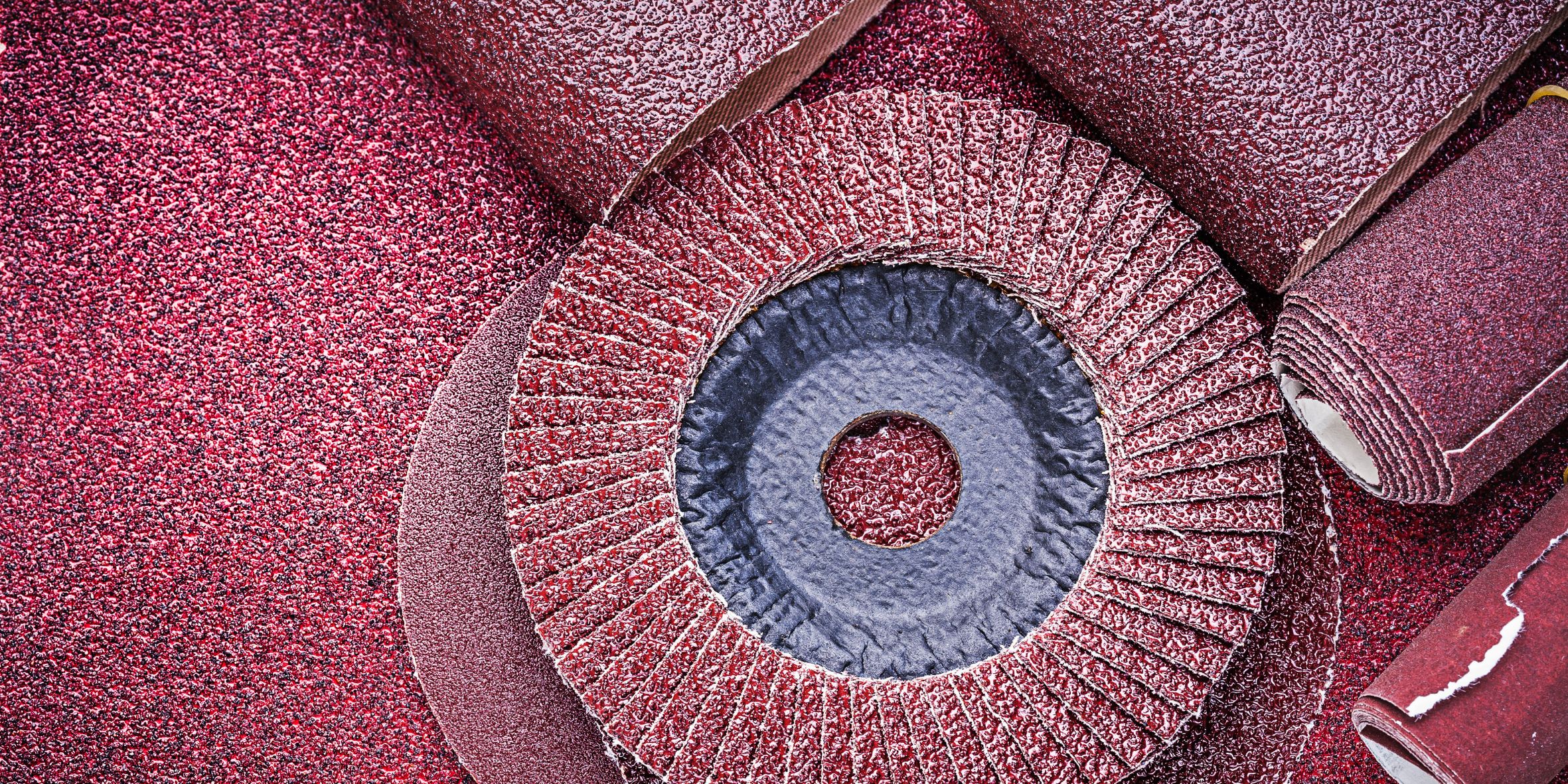

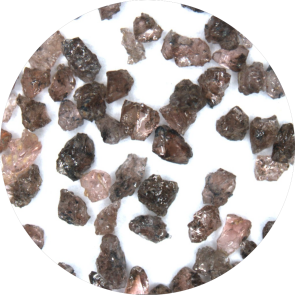

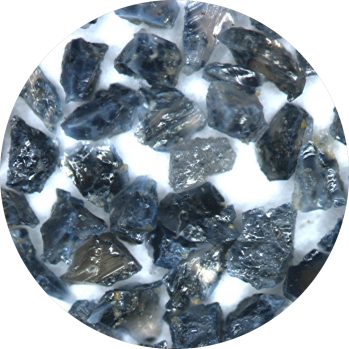

Kowa’s Brown Grits are produced by the fusion of high-quality bauxite in an electric arc furnace at high temperatures. Brown Aluminum Oxide has high compression strength, high toughness, excellent self-sharpening, low coefficient of thermal expansion and cleanliness. Vitrified ranges are with medium Titania, blocky shape and high density. To get the kind of grains, we specially process the ingots, separate the magnetic material, and sieve the grains carefully to get a complete range of grit sizes.

Applications

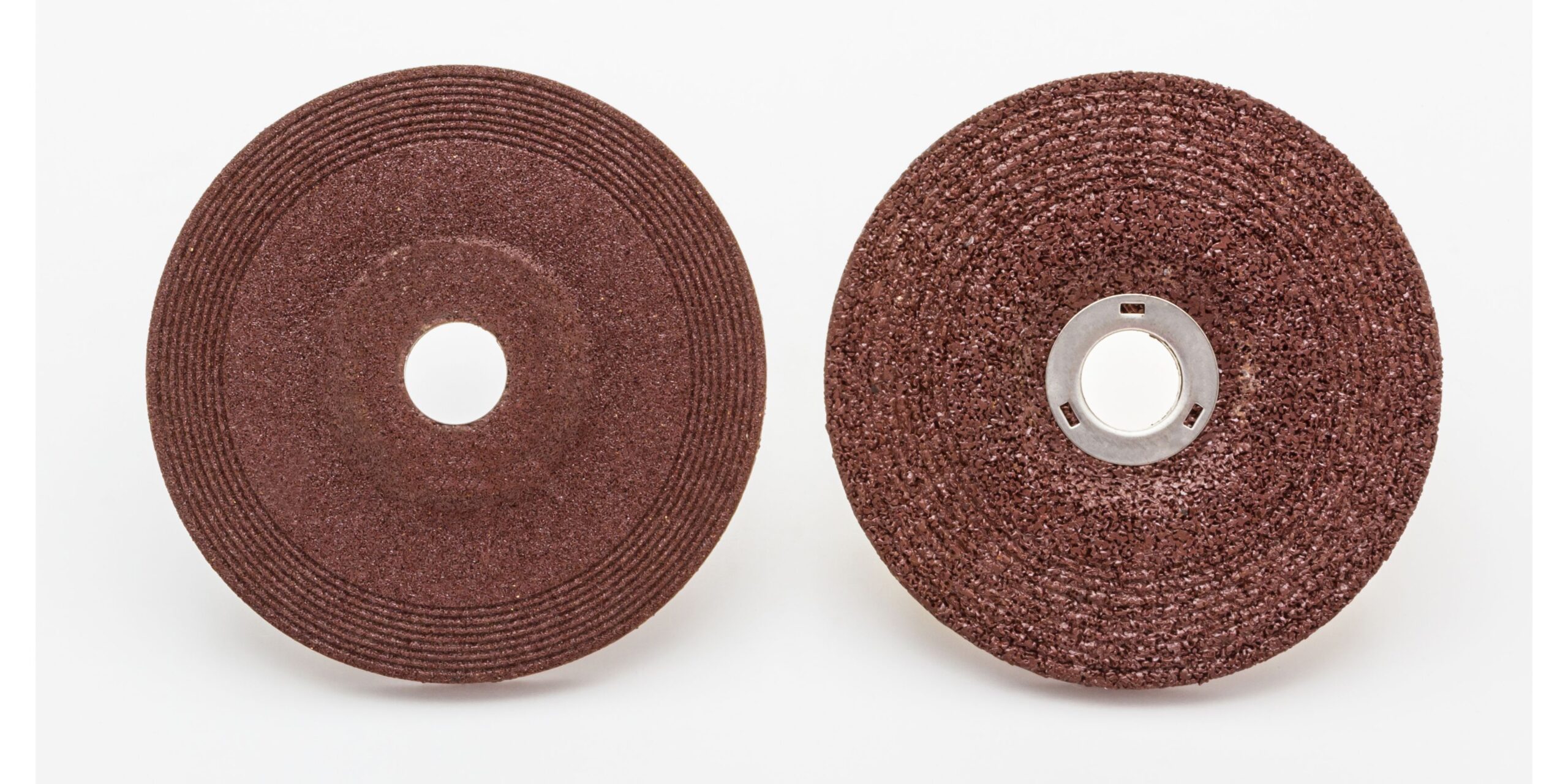

Bonded Abrasives: Kowa’s blocky, tough, high-density grains are ideal for vitrified products requiring strength and durability. And less bulk density ranges are for resin bonded wheels.

Uses: grinding & lapping wheels, rice polishing, gear, crankshaft, cam and tool room wheels, mounted points, razor blades, bearings, thin, roll, and centreless wheels.

Abrasive Blasting: Available from coarse to micron sizes, Kowa Sharp grains combine hardness, toughness, and sharp edges for efficient cleaning, surface prep, and recyclability with minimal dust.

Uses: casting and valve cleaning, turbine blades, automotive parts, paint/rust removal, glass etching, granite/marble engraving, cookware coating, and more.

Refractories: Stable at high temperatures with toughness and thermal shock resistance.

Uses: crucibles, kiln furniture, furnace linings, tap holes, and ramming mass.

Physical Properties

Principal Crystalline Phase

Crystal Color

True Specific Gravity

Mohs hardness

Micro Hardness

Grinding Ability

α-Al2O3

Brown

≥ 3.90 g/cm³

≥ 9.00

HV1800-2200

≥ 0.10

Typical Chemical Analysis(F12-F46):

Al2O3 93.5-94%

TiO2 3-3.5%

SiO2 ≤2.4%

Fe2O3 ≤0.3%

Chemical Composition

ABRR For Blasting/Resinoid Wheel applications Regular Quality

| Specification | Al2O3 | SiO2 | Fe2O3 | TiO2 |

|---|---|---|---|---|

| F12-F54 | 94.00 ± 0.5% | ≤ 2.5% | ≤ 0.30% | 2.0~3.5% |

| F60-F120 | 93.00 ± 0.5% | ≤ 3.0% | ≤ 0.30% | 2.2~3.5% |

| F150-F220 | 91.00 ± 0.5% | ≤ 3.5% | ≤ 0.40% | 2.5~3.5% |

ABRH For Blasting/Resinoid Wheel applications High Quality

| Specification | Al2O3 | SiO2 | Fe2O3 | TiO2 |

|---|---|---|---|---|

| F12-F54 | 95.50 ± 0.5 % | ≤1.8% | ≤ 0.30% | 2.0~3.5% |

| F60-F120 | 94.00 ± 0.5 % | ≤ 1.8% | ≤ 0.30% | 2.2~3.5% |

| F150-F220 | 93.50 ± 0.5 % | ≤ 2.0% | ≤ 0.35% | 2.5~3.5% |

ABV For Vitrified Bonded Wheel Applications

| Specification | Al2O3 | SiO2 | Fe2O3 | TiO2 |

|---|---|---|---|---|

| F12-F54 | 95.50 ± 0.5% | ≤1.5% | ≤ 0.25% | 2.0~3.5% |

| F60-F120 | 94.50 ± 0.5% | ≤ 1.5% | ≤ 0.25% | 2.2~3.5% |

| F150-F220 | 93.50 ± 0.5% | ≤ 1.8% | ≤ 0.35% | 2.3~3.5% |

Grain Sizes Available (Macro)

F12 to F220 In accordance with the current FEPA / JIS / ANSI sieve standards. Other sizes available on request.

Brown Fused Alumina (P)

Brown Fused Alumina (P)

Description

It is one type of non-calcined Brown Fused Aluminium Oxide grain for coated abrasives application, the grain shape is very sharp, the strip and needle shape are well kicked out of the grains

Applications

With the concentrated size distribution and dust collected by well water washing, can be used for producing all kinds of coated abrasives products, such as sand paper, cloth, rolls, belts, etc.

Physical Properties

Colour

Shape

Crystal Form

Specific Gravity

Hardness

Magnetic Material

Brown

Angular, edge sharp

Alpha alumina trigonal system 3.92 2090 Knoop scale, 9.0 Mohs scale 0.0076%

Typical Chemical Analysis(F12-F46):

Al2O3 95.0-94.5%

TiO2 3.0-3.5%

SiO2 ≤ 2.4%

Fe2O3 ≤ 0.3%

Macrogrit Sizes Available (P)

12, 14, 16, 20, 22, 24, 30, 36, 40, 46, 54, 60, 70, 80, 90, 100, 120, 150, 180, 220

M1crogrit Sizes Available (P)

240, 280, 320, 360, 400, 500, 600, 800, 1000, 1200

BFA Ceramic Coated

BFA Ceramic Coated

Description

Kowa’s Ceramic Coated BFA is a new type of abrasive made by deep processing high-quality BFA or high-temperature treated BFA as raw materials, heating at high temperature, and coating a layer of iron oxide on the surface of the grits. The product has the characteristics of large specific surface area, strong hydrophilicity, uniform particle size, high purity, strong adhesion, high grinding and cutting efficiency, and good heat dissipation performance. Its main performance indicators are as follows: compared with ordinary brown corundum, the micro hardness is increased by 10%, the toughness is increased by 10%, the hydrophilicity is increased by 3.5 times, the cutting amount is increased by 3%, and the efficiency is increased by 30-50%.

Applications

Ceramic-Coated BFA: Primary applications: coated and bonded abrasives.

Ceramic-Coated Blue-Fired BFA: Primary application: coated and bonded abrasives, especially those for use on hardened steel and other high-carbide materials.

Physical Properties

Colour

Shape

Crystal Form

Specific Gravity

Hardness

Magnetic Material

Red

Blocky, Angular Alpha alumina trigonal system 3.91 2090 Knoop scale, 9.0 Mohs scale 0.0076%

Typical Chemical Analysis(F12-F46):

Al2O3 95.0-94.5%

TiO2 3.0-3.5%

SiO2 ≤ 1%

Fe2O3 ≤ 0.2%

Ceramic-Coated BFA

Ceramic-Coated Blue-Fired BFA

Grain Sizes Available (F):

12, 14, 16, 20, 22, 24, 30, 36, 40, 46, 54, 60, 70, 80, 90, 100, 120, 150, 180, 220

BFA - Calcined

BFA - Calcined

Description

Kowa’s Calcined BFA is a process of high-temperature calcination at 1050℃ during the production of original BFA, followed by quenching treatment. 1050℃ temperature calcined BFA has the advantages of very low expansion coefficient, good hydrophilicity, improved toughness, and significantly reduced magnetic properties, which can improve the grinding efficiency and accuracy of grinding tools.

Applications

Vitrified Grinding Wheels

Physical Properties

Colour

Shape

Crystal Form

Specific Gravity

Hardness

Magnetic Material

Brown

Blocky, Angular Alpha alumina trigonal system 3.92 2090 Knoop scale, 9.0 Mohs scale 0.0076%

Typical Chemical Analysis(F12-F46):

Al2O3 95.0-95.5%

TiO2 3.0-3.5%

SiO2 ≤ 1%

Fe2O3 ≤ 0.2%

Grain Sizes Available (F):

12, 14, 16, 20, 22, 24, 30, 36, 40, 46, 54, 60, 70, 80, 90, 100, 120, 150, 180, 220, 240

BFA Blue Fired

BFA Blue Fired

Description

After high-temperature calcination at 1300 ℃, the BFA turns blue in color. Impurities present in the abrasive are precipitated or vaporized, making the particle surface rougher and greatly improving the hydrophilicity of the BFA. After calcination, microcracks generated during the crushing process of the BFA and the cooling process of the crystal are bridged, greatly improving the toughness and strength of the BFA and thus enhancing its wear resistance. After high-temperature calcination, weak magnetic fields in the BFA are converted into strong magnetic fields, and after magnetic separation, the BFA becomes purer

Applications

Primary applications: coated abrasives (paper, cloth and belts) and heavy-duty grinding wheels

Physical Properties

Colour

Shape

Crystal Form

Specific Gravity

Hardness

Magnetic Material

Blue

Blocky, Angular Alpha alumina trigonal system 3.92 2090 Knoop scale, 9.0 Mohs scale 0.0076%

Typical Chemical Analysis(F12-F46):

Al2O3 95.0-95.5%

TiO2 3.0-3.5%

SiO2 ≤ 1%

Fe2O3 ≤ 0.2%

Grain Sizes Available (F):

12, 14, 16, 20, 22, 24, 30, 36, 40, 46, 54, 60, 70, 80, 90, 100, 120, 150, 180, 220, 240

White Fused Alumina (F)

White Fused Alumina (F)

Description

White Aluminum oxide is made from the imported high quality alumina by melting above 2000℃ in the electric arc furnace in our plant. It is pure white colour with the main crystal phase α-Al2O3. White fused Aluminum oxide produced in the Tilt furnace has the advantage of high bulk density and low porosity, thus the volume stability and thermal shock resistance can be improved.

Applications

Type 1 : is mainly used as a whitening agent for ceramic glazes and anti-slip paper on composite flooring

Type 2 : is used for Grinding/ Polishing/ Lapping /Metal Preparation/ Anti-Slip/Abrasives/ Refractories/ Vehicle Armor/ Blasting Media/ Microdermabrasion

White Aluminum oxide has two different qualities TYPE1 and TYPE 2.

| Parameters | Type 1 | Type 2 |

|---|---|---|

| Whiteness | Min 75 | Min 65 |

| App density | Min 1.5 | Min 1 |

| Transparency | 80 | 70 |

| PH Value | Max 8 | / |

| Shape | Min 80 | Min 70 |

| B.D F150 | 1.64-1.68 | 1.52-1.58 |

| B.D F180 | 1.62-1.66 | 1.50-1.56 |

| B.D F220 | 1.60-1.64 | 1.48-1.58 |

| Na2O | 0.25%Max | 0.35% Max |

| Milling | Ball | Barmac |

Typical Chemical Analysis(F12-F46):

Al2O3 99.20%

Na2O 0.35%

SiO2 ≤ 0.05%

Fe2O3 ≤ 0.06%

WFA Coated (Iron or zirconium)

WFA Coated

(Iron or zirconium)

Description

Coated WFA is a special abrasive made from high-quality WFA as raw material, which is coated with a layer of metal iridium composite material (Iron or zirconium)on the surface of the WFA through high temperature and heat treatment, and then calcined to produce it. After coated, the toughness of WFA is significantly improved, the surface is rougher, the hydrophilicity is stronger, the self sharpening ability is increased, and the heat dissipation performance is improved. In the process of making grinding wheel products, it can be better combined with binders. The produced grinding tool products have high work efficiency, long service life, and are not easy to burn the workpiece.

Applications

- Fixed grinding tools such as cutting blades, ultra-thin blades, large blades, polishing blades, and grinding blades

- Spraying materials

- Apply grinding tools such as sandpaper, sanding cloth, sanding belt, sponge grinding block, fiber polishing wheel

Physical Properties

Color

Shape

Crystal Form

Specific Gravity

Hardness

Magnetic Material

Red or white

Blocky, Angular Cubic and Angular and Sharp

3.92 2200 Knoop scale, 9.0 Mohs scale 0.0076%

Typical Chemical Analysis(F12-F46):

Al2O3

NaO

SiO2

Fe2O3

99.40%

3.5%

≤ 0.08%

≤ 0.08%

Grain Sizes Available (F):

12, 14, 16, 20, 22, 24, 30, 36, 40, 46, 54, 60, 70, 80, 90, 100, 120, 150, 180, 220

Single Crystal Aluminium Oxide

Single Crystal Aluminium Oxide

Description

Single Crystal Aluminum Oxide is produced in a unique process in which particles of various sizes are formed naturally during production, without the need for mechanical crushing. Single Crystal Aluminum Oxide is light blue in color (when fired between 300°C and 1280°C) and it has the advantages of extremely high hardness, sharp multi-prism cutting edges, stable bulk density, and excellent grinding performance with relatively low heat-generation.

Applications

Grinding and Cutting Wheels:Used in the manufacture of rust-free vitrified, resin-bonded and rubber-bonded wheels that are perfect for grinding or cutting high hardness, high toughness metals such as heat-resistant alloy steel, titanium alloy steel, austenitic stainless steel, decorative stainless steel, or other easily burned work pieces.

Physical Properties

Colour

Shape

Crystal Form

Specific Gravity

Hardness

Magnetic Material

Light Blue

Blocky, edge sharp

Alpha alumina trigonal system 3.92 2200 Knoop scale, 9.0 Mohs scale 0.0076%

Typical Chemical Analysis(F12-F46):

Al2O3 ≥ 99.20%

TiO2 ≤ 0.45%

SiO2 ≤ 0.07%

Fe2O3 ≤ 0.08%

Grain Sizes Available (F):

12, 14, 16, 20, 22, 24, 30, 36, 40, 46, 54, 60, 70, 80, 90, 100, 120, 150, 180, 220

packing

20 Kg/25Kg Paper bags, 50 Lbs Paper bags, 2000lbs / 1 MT Jumbo Bags.